What Are Emergency Stops? A Guide to E-Stops, Emergency Buttons, and More

Emergency stops, commonly referred to as E-stops, emergency buttons, or kill switches, are critical safety devices used in industrial and commercial environments. These devices are designed to quickly shut down machinery or systems in the event of an emergency, preventing injury, equipment damage, or hazardous situations.

How Do Emergency Stops Work?

An emergency stop is a fail-safe control mechanism that, when activated, halts the operation of connected equipment immediately. Unlike standard stop functions, which may follow a controlled shutdown sequence, E-stops override all commands and bring machinery to a complete stop as fast as possible.

Most emergency stop buttons are designed to be highly visible, typically colored red with a yellow background, in compliance with ANSI (American National Standards Institute) and OSHA (Occupational Safety and Health Administration) standards. They are often push-to-stop and twist-to-reset, ensuring that accidental activation is minimized while maintaining ease of use during emergencies.

Other Names for Emergency Stops

Depending on the industry and region, emergency stops may also be referred to as:

• E-Stop Buttons

• Kill Switches

• Panic Buttons

• Emergency Shutoff Switches

• Safety Stop Buttons

• Emergency Power Off (EPO) Switches

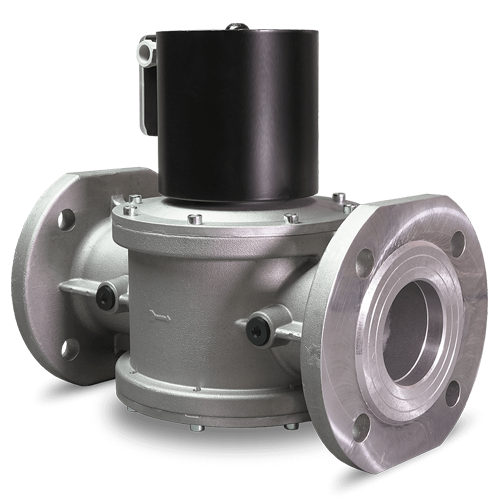

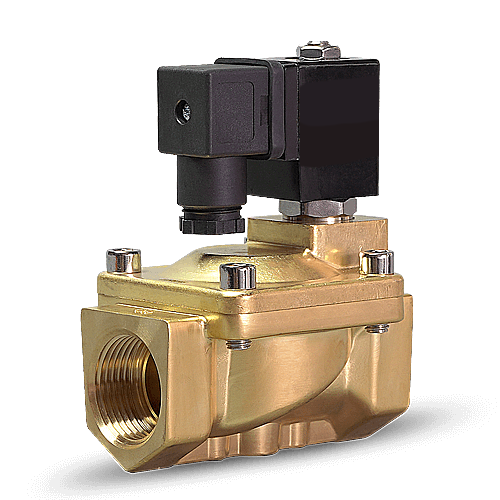

Emergency Stops for Solenoid Valves

The emergency stops available at Valve Shop are specifically designed for use with solenoid valves. These emergency stop buttons are crucial for controlling fluid and gas flow, ensuring a rapid shutdown of systems in case of an emergency. By cutting power to the solenoid valve, the E-stop effectively stops the flow of media such as air, water, or other process fluids, preventing potential hazards in industrial applications.

Where Are Emergency Stops Used?

Emergency stop buttons for solenoid valves are used in a wide range of industries and applications, including:

• Manufacturing Facilities – To shut down fluid and gas control systems in case of malfunction or hazard.

• Process Automation – To ensure immediate stoppage of solenoid-controlled processes.

• Industrial HVAC Systems – To prevent gas leaks and fluid flow issues.

• Chemical and Pharmaceutical Plants – To maintain safe operation of solenoid-controlled liquid handling systems.

• Water and Wastewater Treatment – To stop the flow of chemicals and water in emergency situations.

Emergency Stop Regulations in the U.S.

In the United States, emergency stops must comply with several safety standards, including:

• OSHA 29 CFR 1910.217 – Mandates the presence of emergency stops in certain industrial settings.

• ANSI B11.19-2019 – Provides guidelines for machine safeguarding, including E-stop requirements.

• NFPA 79 – Covers electrical safety for machinery and the use of emergency stop functions.

These regulations ensure that emergency stop systems are properly designed, placed, and maintained to maximize safety and efficiency in the workplace.

Choosing the Right Emergency Stop Button

Selecting the correct emergency stop for solenoid valve applications depends on several factors, including:

• Size and Visibility – Must be easily identifiable and accessible.

• Durability – Suitable for industrial or outdoor environments.

• Wiring and Integration – Compatible with solenoid valve control systems.

• Reset Mechanism – Usually twist-to-reset or pull-to-reset for controlled reactivation.

For a variety of high-quality emergency stop solutions for solenoid valves, visit Valve Shop’s Emergency Stop Selection.

Final Thoughts

Emergency stops are an essential component of workplace safety, offering a quick and effective way to halt dangerous situations. Whether referred to as E-stops, kill switches, or emergency buttons, their purpose remains the same: to provide immediate safety intervention when it matters most.

Ensure compliance with U.S. safety regulations and choose the right emergency stop for your solenoid valve applications by exploring available solutions today!