Choosing the correct solenoid valve is a responsibility that rests on the project manager’s shoulders. A mismatch between valve design and application can lead to leaks, failures and delays.

Match the valve to the fluid

Liquids and gases have different properties. High‑density fluids, corrosive chemicals and flammable gases all require specific materials and seals. Materials that resist corrosion and swelling ensure long service life

When working with medical fluids or fuels, use inert materials that do not react with the fluid.

Plan for temperature extremes

Every valve has minimum and maximum temperature ratings

Temperature changes affect fluid viscosity and can cause materials to expand or contract. Low temperatures may embrittle elastomer seals, while high temperatures can reduce coil efficiency and require higher voltage. Choose valves rated for your full operating range, including startup and shutdown conditions.

Consider external pressures and forces

If your valve will operate under high external pressure—underground or underwater—the housing must withstand the environment

Applications in vehicles or machinery may expose valves to vibration and shock. Specify connectors and mountings that can tolerate these forces

Address contamination risks

Contamination from debris or wear particles can damage a valve’s internal components

Use upstream filters to remove particles, or select valves designed with larger passages that allow debris to pass through. Inspect systems before installation to minimise existing contamination.

Verify the power source

Solenoid valves rely on a stable electrical supply. In battery‑powered systems, voltage may drop as batteries discharge. Ensure the coil can operate within the expected voltage range

Meet industry standards

Different industries have specific requirements for valve performance and safety. Standards from organisations such as ISO, ASME and ANSI set minimum levels of quality and reliability

Verify that the valves you select meet or exceed relevant standards for your application, whether it involves gas distribution, potable water or industrial fluids.

Steps for project managers

Define the application: Identify fluid properties, pressure ranges, temperature extremes and environmental conditions.

- Review standards: Check which industry standards apply to your project.

- Select materials: Choose valve materials compatible with the fluid and environment.

- Plan for maintenance: Design the system to allow easy access for inspections and replacements.

- Document decisions: Record the reasoning behind each selection to aid future maintenance and compliance.

By following these steps and consulting technical guides, you ensure that solenoid valves in your project perform reliably. Investing time in selection and specification avoids costly retrofits later and helps deliver safe, efficient systems that meet regulatory expectations.

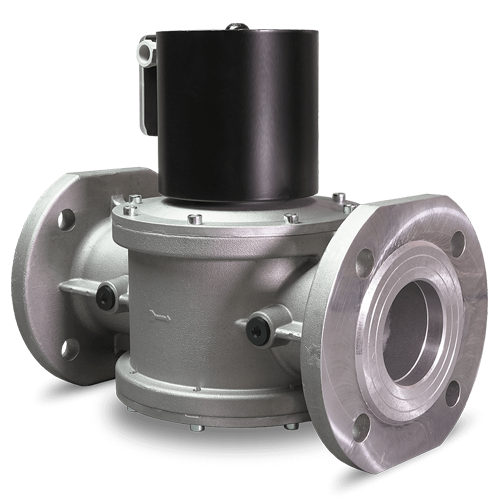

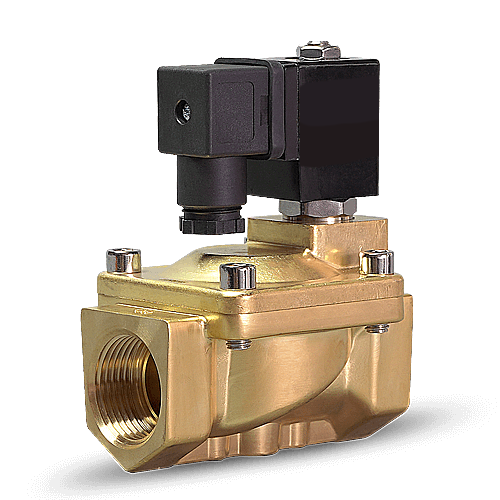

When it comes to purchasing Gas solenoid valves, there is no better choice than ValveShop.us. We offer an extensive selection of gas valves, ranging from compact 1/2-inch models to massive 6-inch gas solenoid valves, ensuring that we have the right solution for your specific needs.

Have any questions - You can call us on +1 (866) 267-6730 or email: enquiries@valveshop.us